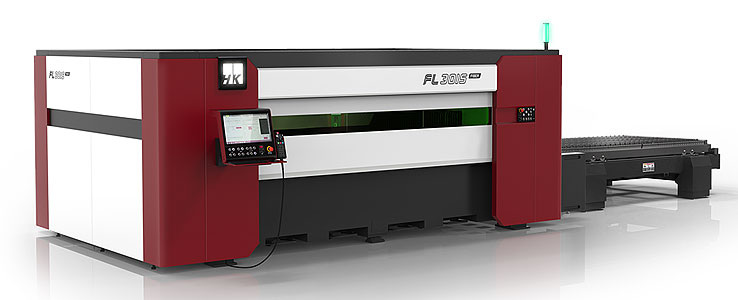

Laser Cutting Machine Germany

When the equipment is stopped, always clean the guide rails, wipe the rack of the equipment, and often apply lubricating oil on the guide rails to ensure that there is no debris;

You should understand the structural structure of a laser cutter kit before you build it.